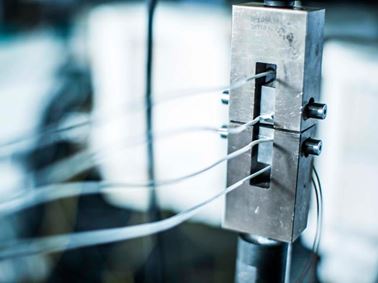

When operating in extremely challenging and hard-to-reach environments, there really is no margin for error – and no one can accept a component failure in-service. Element’s weld testing services help to ensure your welding process is correct and sustainable and meets the quality and safety standards, offering you peace of mind, alongside long-term cost savings.

Welding, as the joining method of choice within offshore structures, applies to almost all components within subsea systems. From the complex structures that are lowered to the seabed, wellheads, and pipes, there is a myriad of components that need to be joined by welds. Therefore, verifying the properties and testing the lifecycle of these welds is of paramount importance under harder to simulate ‘realism’, especially when considering defective welds are often the ‘weakest link’ in terms of a system’s viability.

拥有超过100年的能源部门的专业技能,Element is a recognized leader in the provision of welding services across the world. Our highly experienced and certified weld technology experts and PCN and CSWIP-qualified weld inspectors provide critical welding-related services including weld qualification testing, development of weld procedures for specification and code compliance, weld failure analysis, weld quality analysis, and welding process auditing and improvement services.

With globally located, fully ISO 17025 accredited laboratories, we can simulate real-time weld testing conditions for welds and offshore components and their behavior in the field, including increased temperatures, higher pressures, more aggressive and corrosive conditions, and ultra-deepwater environments.

To help you keep up with ever-changing technological advancements, we continually develop new techniques andweld test methods. OurCrack Tip Opening Displacement (CTOD)Single Edge Notch Bending (SENB) testing for welded materials is being progressively replaced with Single Edge Notch Tension (SENT) testing andfailure analysis. Both tests can be conducted in a simulated service environment. The combination of a highly diverse range of industry-recognized international and national codes and standards that we work to, together with the real world experiences of our welding specialists, enables Element to provide our clients with the certainty that the offshore projects we are involved in are as successful and safe as possible.

Whether your requirement is in weld procedure or welder certification, weld testing, inspection or forensic failure analysis, our welding services can support you at every stage of the asset life cycle.

For more information about our weld testing services or to request a quote,contact us today.

Our Services

Welding Inspection & Monitoring

Element offers CSWIP, PCN and CWI welding specialists' expertise to provide a comprehensive range of welding inspection and monitoring services.

Read more

Weld Procedure/Welder Qualification & Certification

Element provides WPQ, WPQR, WPS, and WQC services to help you achieve welder qualifications and certifications as per requested codes and standards.

Read more

Mechanical Testing

Element's mechanical tests show whether a material or part is suitable for its intended mechanical applications.

Read More

Non-Destructive Testing (NDT)

Element's NDT services comply with a wide variety of industry standards, government contracts, military specifications and unique customer requirements.

Read More

Failure Analysis

Find out how Element's global team of failure analysis experts learn from the past, to help prevent failures in service.

Read More

Engineering Critical Assessment (ECA) Services

Element provides Engineering Critical Assessment (ECA) to determine if a flaw in welded structures is safe from brittle fracture, fatigue, or creep.

read more

Weld Fatigue Testing of Steel Catenary Risers

Element’s full-scale pipeline testing facility performs testing on steel catenary risers in our laboratory and on-site at the point of fabrication.

READ MORE

Fracture Mechanics

Find out how Elements fracture mechanics services support the Oil and Gas Upstream sector

Read more

making certain for nearly 190 years

More from Element

Immersion Ultrasonic Testing

Element has developed world-leading capabilities in IUT (Immersion Ultrasonic Testing) to provide state-of-the-art testing support for the Oil and Gas industry.

Read More

Coatings Testing

Find out about our Oil & Gas coatings testing services and how we help to make certain that materials, products and pipelines are protected from corrosion, ultraviolet light, water penetration, heat, abrasion and chemicals.

Read More

Local laboratories, global platform

Doing business with one of our laboratories enables our clients' access to our global platform of expertise, capacity and capabilities.

READ MORE